Comparative analysis of ultrasonic level gauge and radar level gauge

With the continuous improvement of industrial automation level, liquid level measurement technology plays a crucial role in multiple industries. Among them, ultrasonic level gauges and radar level gauges perform well in various complex industrial environments due to their non-contact measurement methods. This article will delve into the characteristics, working principles, application scenarios, and respective advantages and disadvantages of these two liquid level measurement technologies, and demonstrate their performance in practice through specific cases.

1、 Working principle

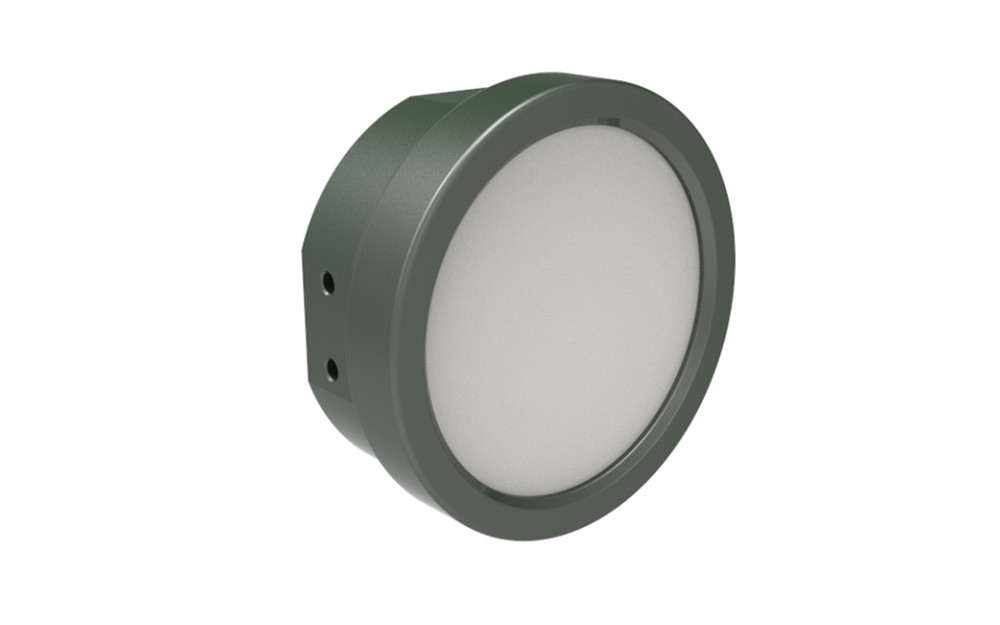

The working principle of ultrasonic level gauge is to utilize the propagation characteristics of ultrasonic waves in air. There is a transducer inside the device that can emit ultrasonic pulses and receive sound waves reflected back from the surface of the object being measured. By calculating the time required for sound waves to travel back and forth, and considering the variation of sound speed with temperature, the distance of the measured object can be obtained. This method is simple and reliable, but it has certain requirements for environmental conditions.

Radar level gauges utilize the reflection characteristics of microwave signals. The radar level gauge emits microwave signals, which are reflected when they encounter the surface of the measured medium. After receiving the reflected signal, the radar equipment calculates the height of the liquid level or fixed position based on the time difference required for the signal to travel back and forth. A significant advantage of radar technology is that its signals can penetrate non-metallic materials, so radar level gauges can be installed at the top of containers without direct contact with the medium.

2、 Technical features

The advantages of ultrasonic level gauge are:

- Low cost: Compared to radar level gauges, ultrasonic level gauges have lower costs.

- Easy to install and maintain: The structure is simple, and installation and daily maintenance are relatively easy.

- Non contact measurement: suitable for situations where pollution prevention is necessary.

Its limitations mainly include:

- Environmental factors have a significant impact: factors such as steam, bubbles, and temperature changes can all affect the measurement results.

- Not suitable for vacuum environment: Ultrasonic waves require medium propagation, so they are not suitable for vacuum conditions.

- Limited measurement range: generally suitable for measurements over shorter distances.

The characteristics of radar level gauges include:

- Strong anti-interference ability: not affected by temperature and pressure changes, suitable for various media.

- Wide applicability: It can measure almost all types of media, including corrosive or viscous media.

- High precision measurement: Provides very high measurement accuracy, suitable for situations where precise control of liquid level is required.

However, radar level gauges also have some shortcomings:

- High cost: The initial investment for radar level gauges is higher than that for ultrasonic level gauges.

- High installation requirements: antenna type and installation location need to be considered to ensure optimal measurement results.

3、 Application scenarios

Ultrasonic level gauges have a wide range of applications, especially in cost sensitive applications. For example, in industries such as municipal water supply systems, sewage treatment facilities, and food processing, ultrasonic level gauges are widely used due to their affordability. Such applications typically do not require extremely high measurement accuracy, but require reliable and continuous monitoring.

Radar level gauges are more commonly used in applications that require high measurement accuracy, such as petroleum refining, chemical production, pharmaceuticals, and other industrial fields. These industries often involve corrosive substances or extreme environments, and radar level gauges have become an ideal choice due to their excellent stability and anti-interference ability.

4、 Measurement accuracy and anti-interference ability

In terms of measurement accuracy, radar level gauges can usually provide higher accuracy than ultrasonic level gauges due to the characteristics of their microwave signals. Especially in long-distance measurement, the advantages of radar level gauges are more obvious. The microwave signal of the radar level gauge can penetrate most non-metallic materials, which allows it to obtain accurate data even at the top of the container.

Although ultrasonic level gauges have good accuracy in short distance measurements, their stability in complex environments is not as good as radar level gauges due to the influence of various factors such as steam, bubbles, etc. during the measurement process.

Ultrasonic level gauges and radar level gauges have their own advantages, and users should choose the most suitable measurement tool based on actual application needs, environmental conditions, and budget constraints. For general application scenarios and cost sensitive projects, ultrasonic level gauges may be a better choice; In situations where high-precision measurement is required or complex working conditions are faced, it is recommended to use radar level gauges. Regardless of which one is chosen, a reasonable evaluation of various performance indicators and selection based on actual conditions are necessary to ensure that the final measurement results meet expectations.